We’re here to assist with any inquiries or support you need. Reach out to us anytime, and we’ll respond promptly to help you.

- June 09, 2021

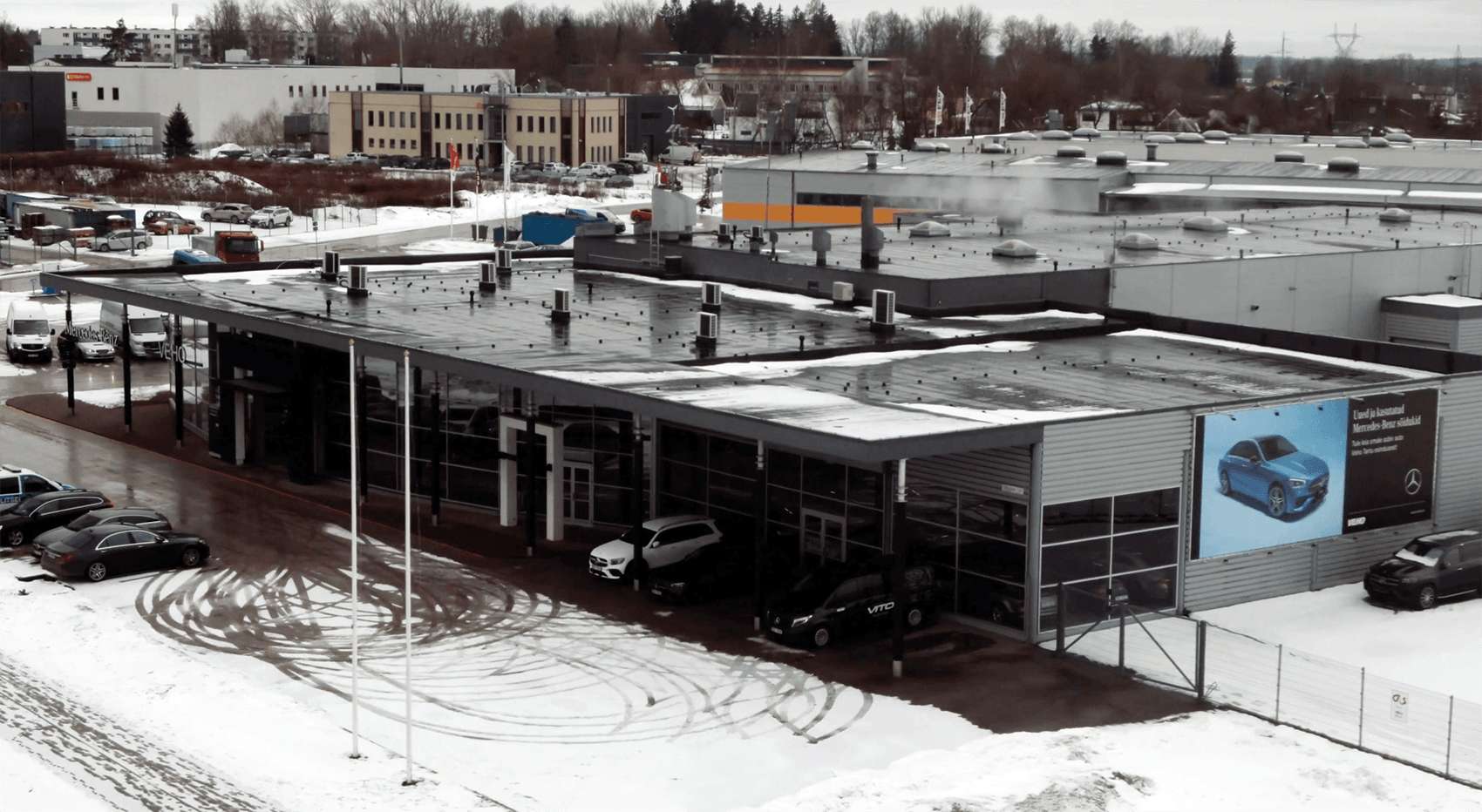

VEHO TARTU

-

Heated floor area

2807 m2 -

Year of construction

2004 -

Heating control

Ouman -

Ventilation control

Regin

Learn how KUTUN Automotive helped Veho to reduce their energy consumption by 42%.

Veho Estonia was looking for a way to cut energy consumption and carbon emissions. They were already using energy-efficient lighting in all of their workshops, showrooms, and offices, but they wanted to do more – The solution was Kutun Remap.

KUTUN Remap Stage 1.

This unit is designed to help you get the most out of your existing setup without having to replace anything.

Installation

Veho’s HVAC equipment is properly maintained, and equipped with market-leading controllers.

Kutun Remap unit is installed and connected to the heating and ventilation controllers on a parallel basis, while also being equipped with air quality sensors in the workshop, showroom, and offices.

The first week after installation, KUTUN Automotive collected data to set the baseline for optimization.

Optimization

Initial optimization was done manually at first based on collected data and inspection carried out by KUTUN Automotive’s team.

During the following weeks, Kutun Remap was able to build characteristics of how well the system and the building were performing.

We integrated DMS software with KUTUN Remap for better control. Now everything can be analyzed and controlled in one place.

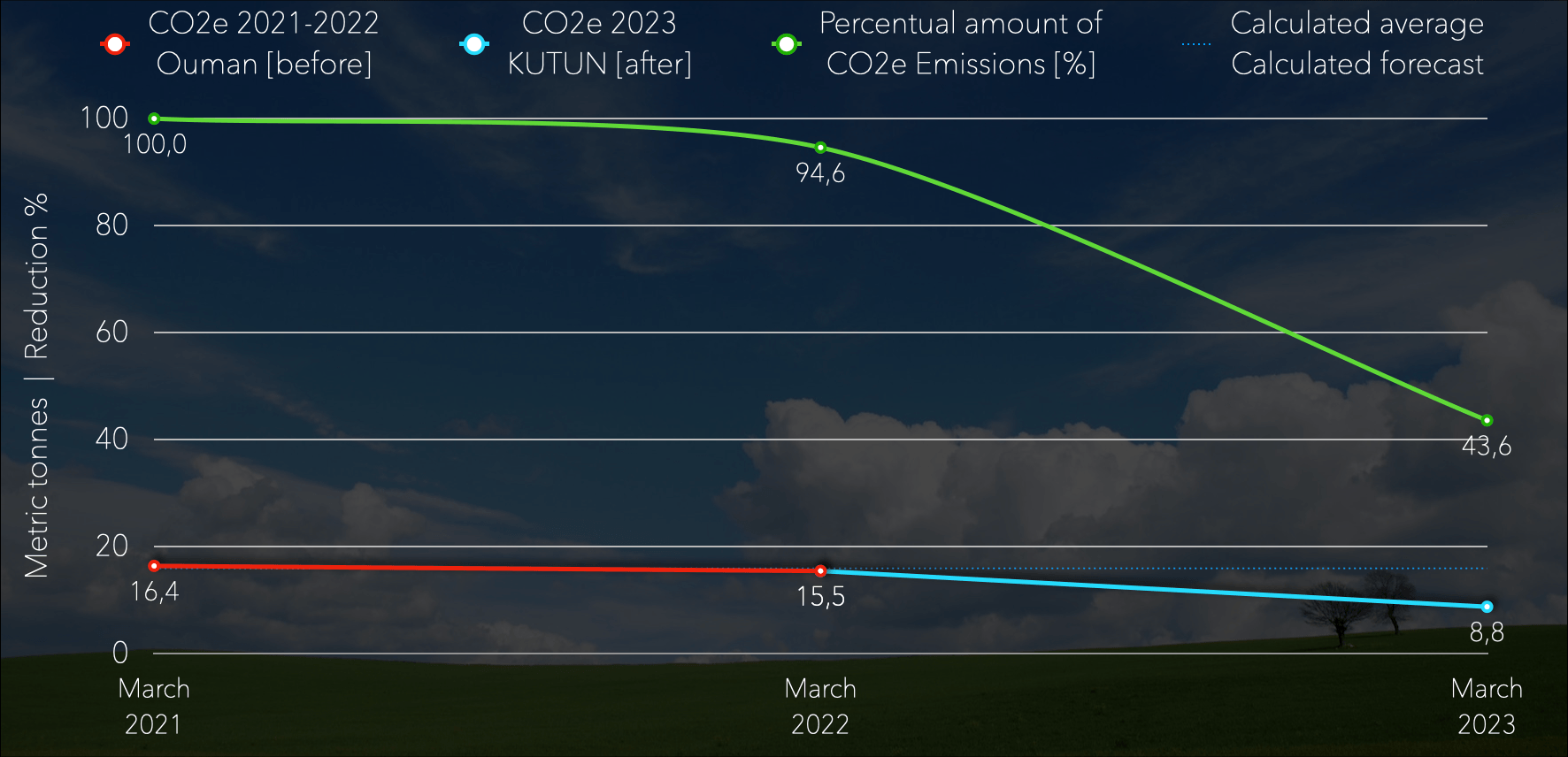

Results

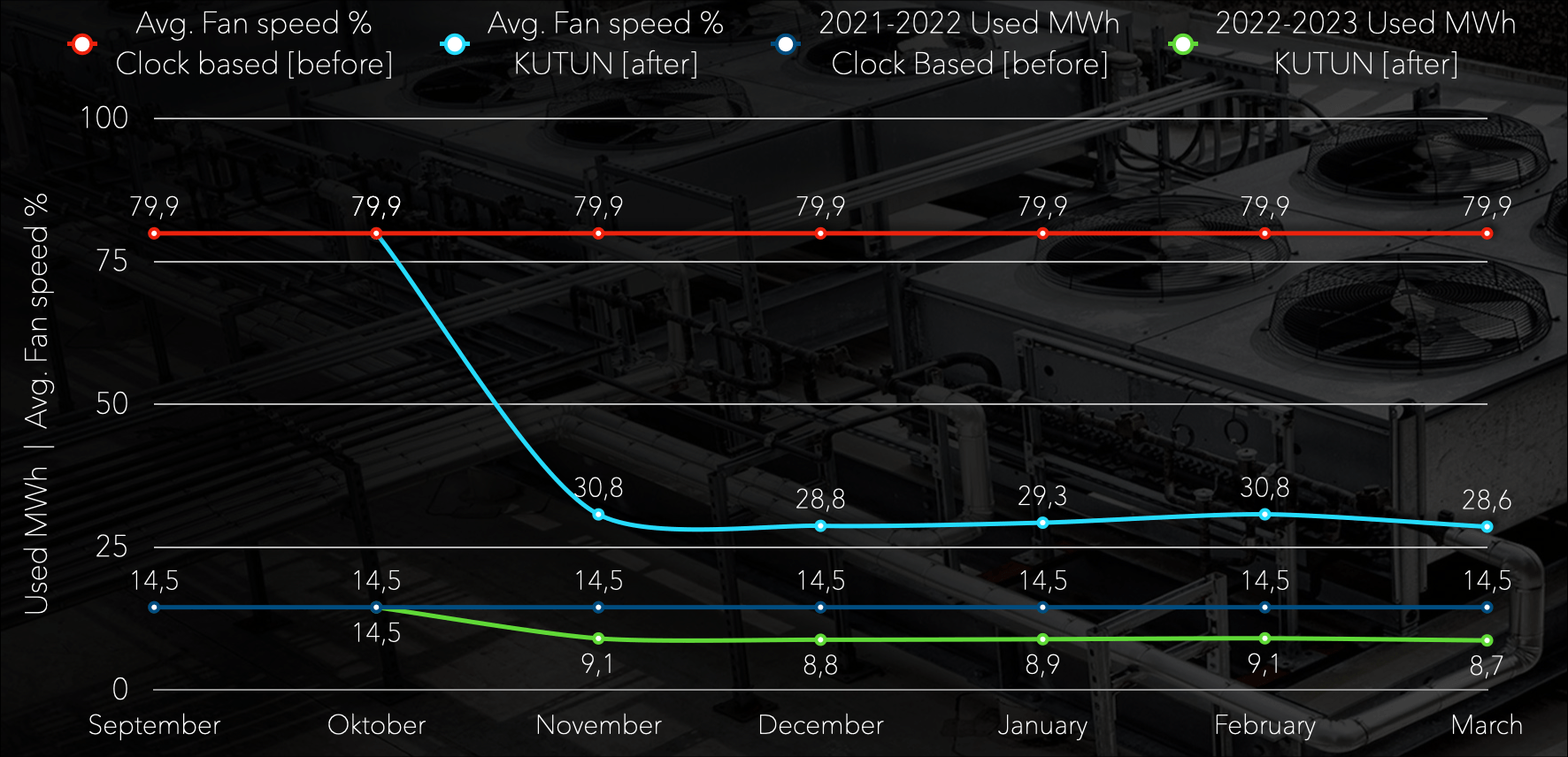

KUTUN Remap helps to save approximately:

6 Megawatt hours of electricity per month.

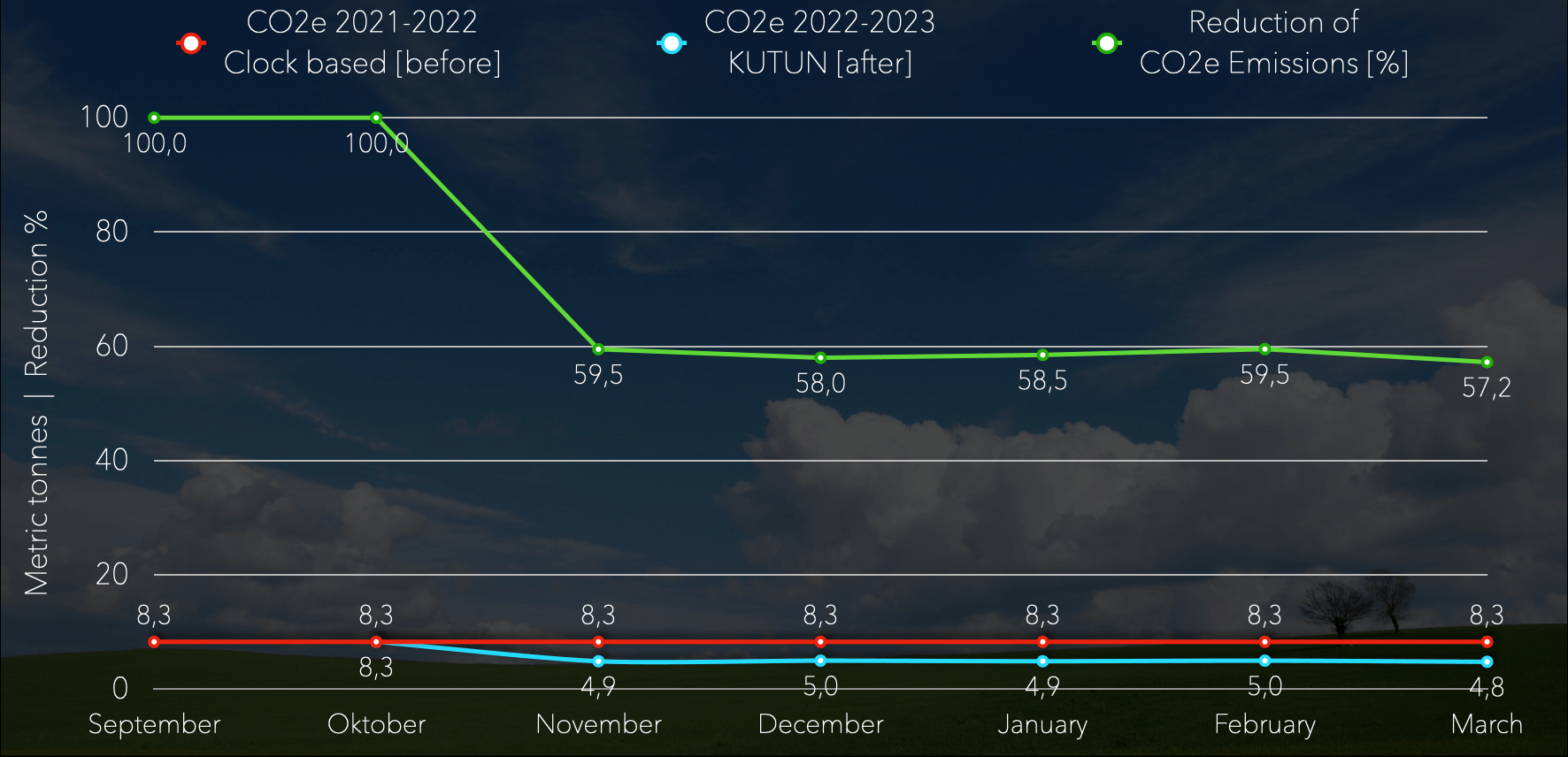

KUTUN Remap helps to reduce CO2 emissions approximately:

3 metric tons per month.

Savings are fully documented and traceable.

“After analyzing the characteristics of the building, the dealership’s daily workflow, as well as the data from heating and ventilation units, we decided to split the workshop into multiple zones.”

KUTUN Remap Stage 3.

Stage three is a custom solution which includes the Kutun Remap unit and additional hardware.

Installation

The system is already equipped with the KUTUN Remap unit, which allows us to change the heating and cooling logic.

For extra savings, we decided to divide the workshop into four smaller areas, plus leave the detailing area fully autonomous as it was before.

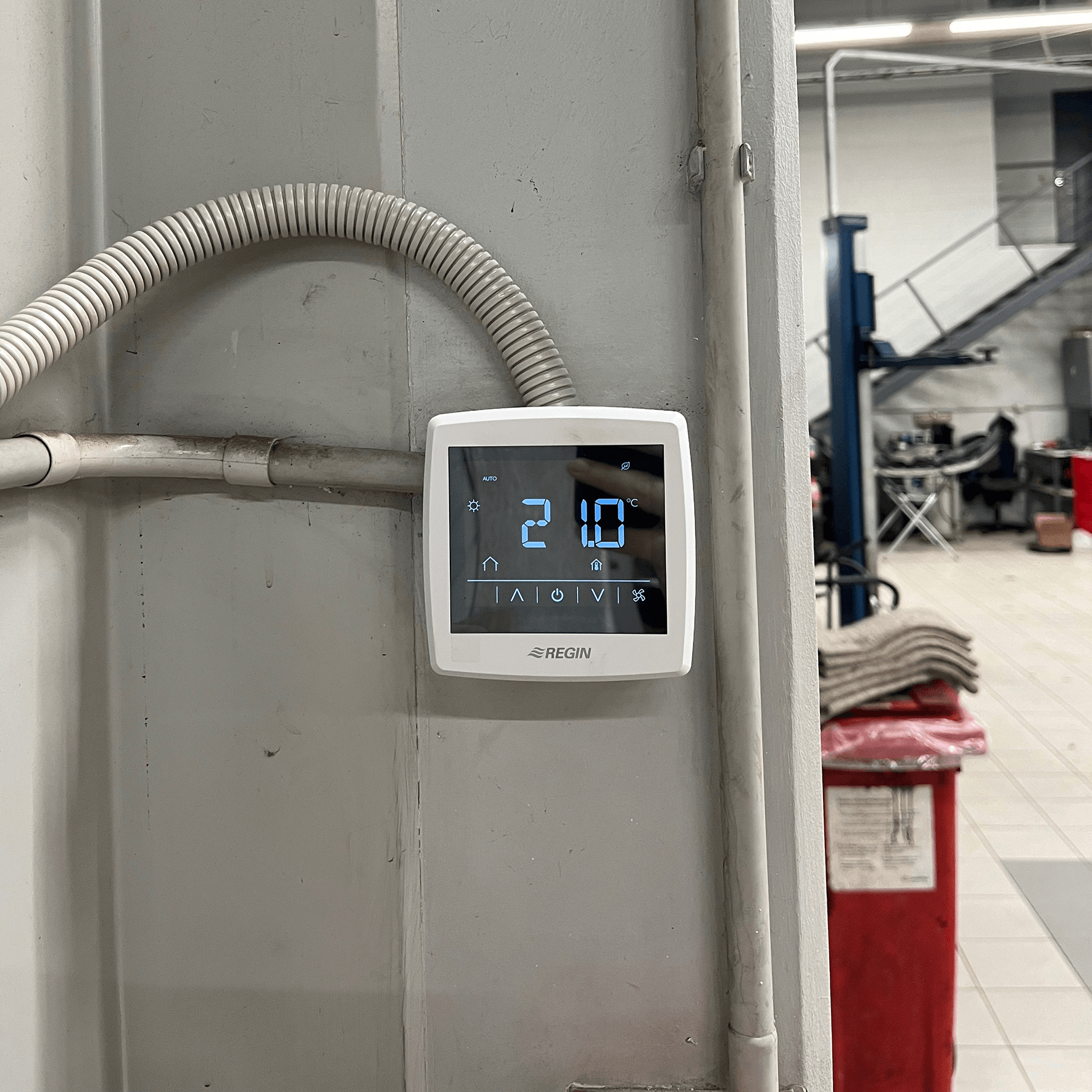

To achieve this, we installed five new Modbus controlled room thermostats from Regin.

Optimization

Thanks to individual measurement points, KUTUN Remap was able to monitor how each area was performing.

For example, how the sun, wind and other elements affected each area during the day, and control the HVAC accordingly.

This, together with DMS software integration, gave us the needed info to rethink the whole heating logic.

Results

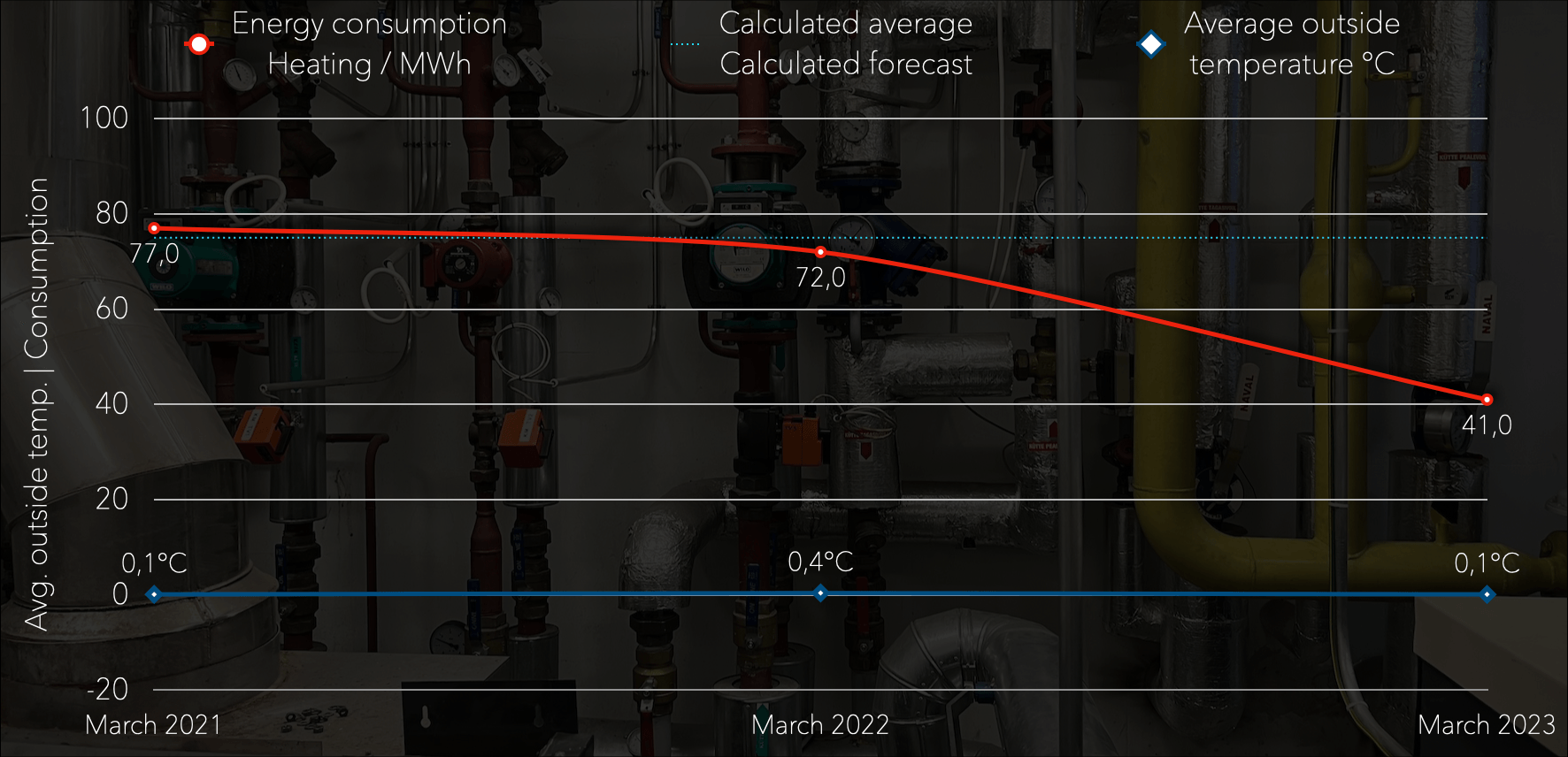

In March 2023, KUTUN Remap helped to save approximately:

6 Megawatt hours of electricity, plus

33 Megawatt hours of heating energy (-42%).

This equals almost 10 metric tons of CO2 emissions.

Savings are fully documented and traceable.